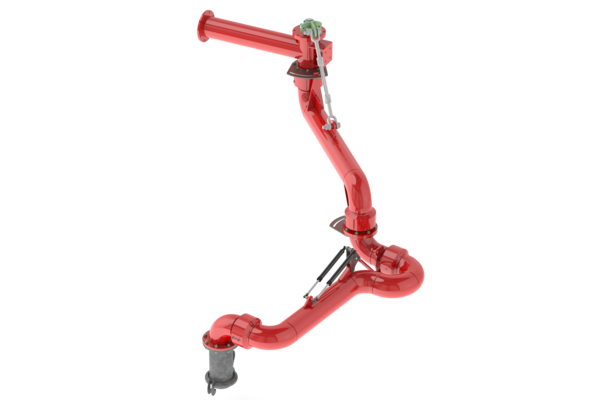

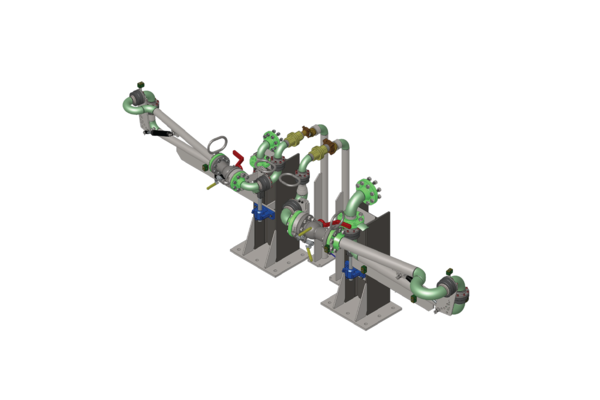

Custom/Specialty Loading Arms

Liquip manufactures custom/specialty loading arms for a wide range of liquid transfer applications. Nearly any application currently using a hose is a potential custom loading arm application.

Our custom/specialty loading arms are built to meet your unique applications and specifications, whilst optimising safety, performance and efficiency.

With an already extensive range, and over 55 years of quietly setting industry benchmarks, Liquip is able to respond quickly and can tailor a custom solution to specific and specialised requests.

Using our specialised gas strut design that Liquip is renowned for, we can tailor design an arm to suit your operational requirements.

Please contact Liquip if you have any questions or enquiries regarding your application.

Aside from standard loading arm applications, some of the applications using Liquip loading arms include:

- Liquid sugar syrup loading of rail cars.

- Waste water unloading of rail cars.

- Rail car locomotive refuelling.

- Mine service vehicle refuelling.

- Aviation refueller loading.

- Fuel barge loading and unloading.

- Specialised gas loading.

- Wide range of chemical loading.

- Military/defence refuelling.

- Wide range of acid loading.

- Fire suppression arms.

- Drum/Tote loading.

Interested?

Contact us for a quote or for further information.

Are you enquiring about multiple products? Consider using our Enquiry Cart