Load Ratings from 3,400 lb / 1.5 tonnes to 202,000 lb / 90 tonnes

Up to: 90 tonnes

Extreme Heavy Duty (F900)

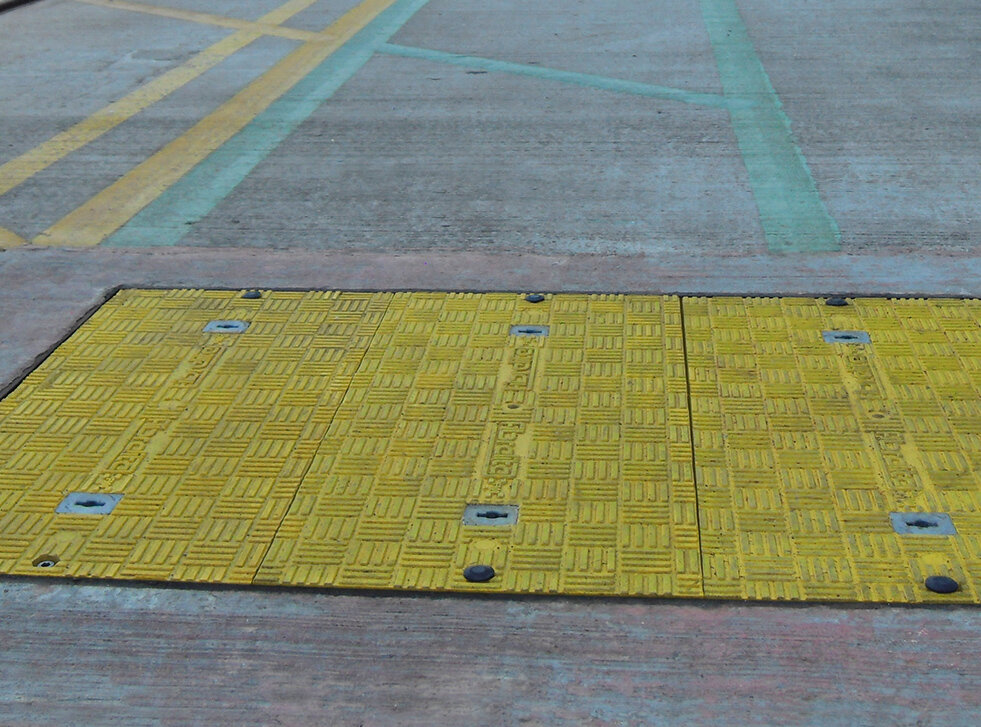

For use in areas where extremely high wheel loads

are imposed such as docks or airport runways

Up to: 60 tonnes

Super Heavy Duty (E600)

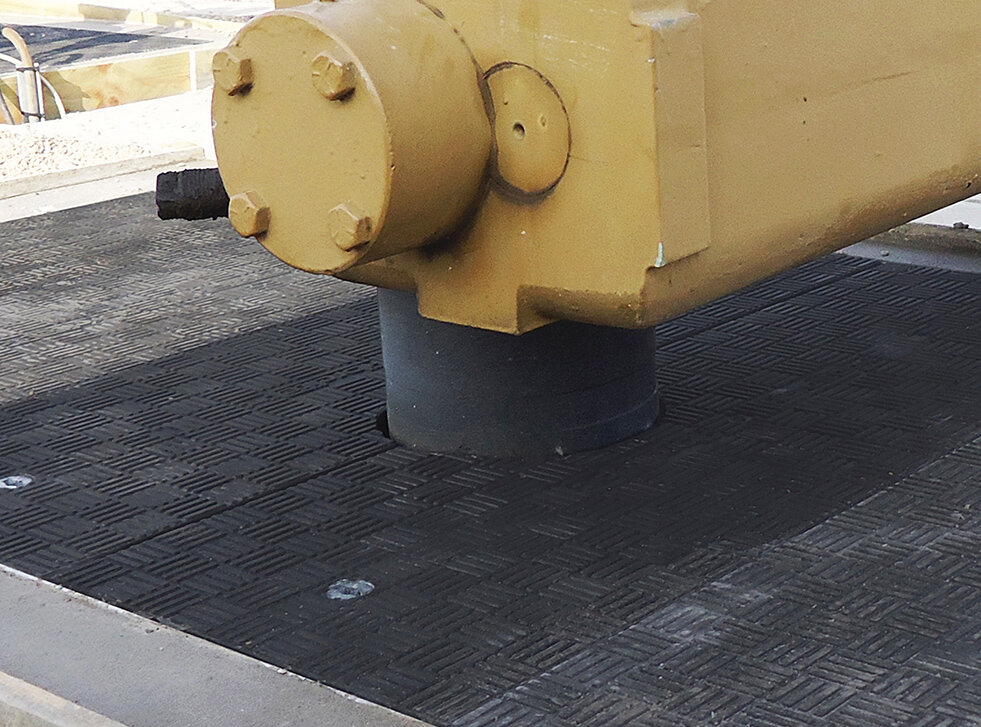

For use in areas where extremely high wheel loads

are imposed such as loading areas

Up to: 40 tonnes

Heavy Duty (HS25/D400)

For use in areas with frequent bus or heavy truck

traffic, including carriageways and hard shoulders

Up to: 25 tonnes

Standard Duty (C250)

For use in areas with frequent bus or heavy truck

traffic, including carriageways and hard shoulders

Up to: 20 tonnes

Standard Duty US (HS20)

For use in car parking lots, petrol stations, industrial

sites and areas with slow moving traffic

Up to: 5 tonnes

Medium Light Duty

For use in raised curb locations where

light vehicular access is possible

Light Enough to Remove By Hand. Strong Enough for Any Application A15-F900

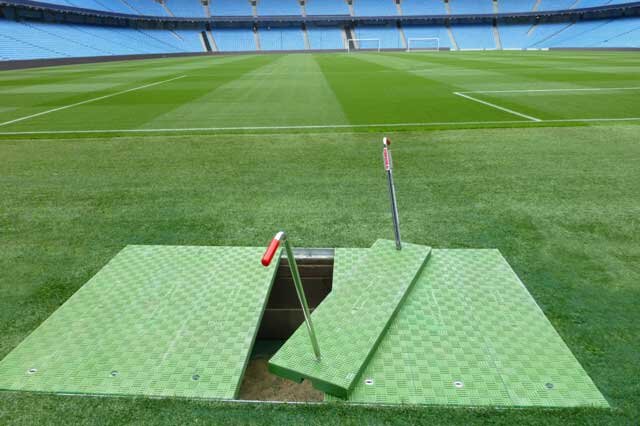

With an unrivalled strength-to-weight ratio, lightweight Fibrelite trench covers are available in a range of load ratings (from 1.5 to 90 tonnes) to suit every application and every budget. Easy-to-remove, safe and available in an almost limitless range of RAL colours, sizes and configurations, each cover is designed to deliver years of trouble-free service even in the harshest environments.

Not All Composite Covers Are the Same

Although GRP composite covers are now increasingly preferred to the traditional metal or concrete options – not every composite cover performs to the highest standards year after year.

Fibrelite trench covers are a high-performance product created via resin transfer moulding (RTM) to create a durable, monolithic cover that you can truly fit-and-forget. What’s more, each one has been individually engineered in our own manufacturing facilities.

We’re Trusted by Specifiers, Architects and Engineers Worldwide

Fibrelite has been at the forefront of composite quality and innovation since 1980 when we designed the world’s first GRP composite manhole cover for the retail petroleum industry. Our high-performance, lightweight, safe-to-lift composite covers – including the unique F900 load-rated trench cover – are now selected by specifiers, architects and engineers worldwide.

Why Choose a Fibrelite Trench Cover? Benefits at a Glance

- Load ratings from A15 (3,400lb) to F900 (202,000lb) (BS EN 124)

- Bespoke and custom sizes available

- The widest range of GRP trench covers available to suit every requirement

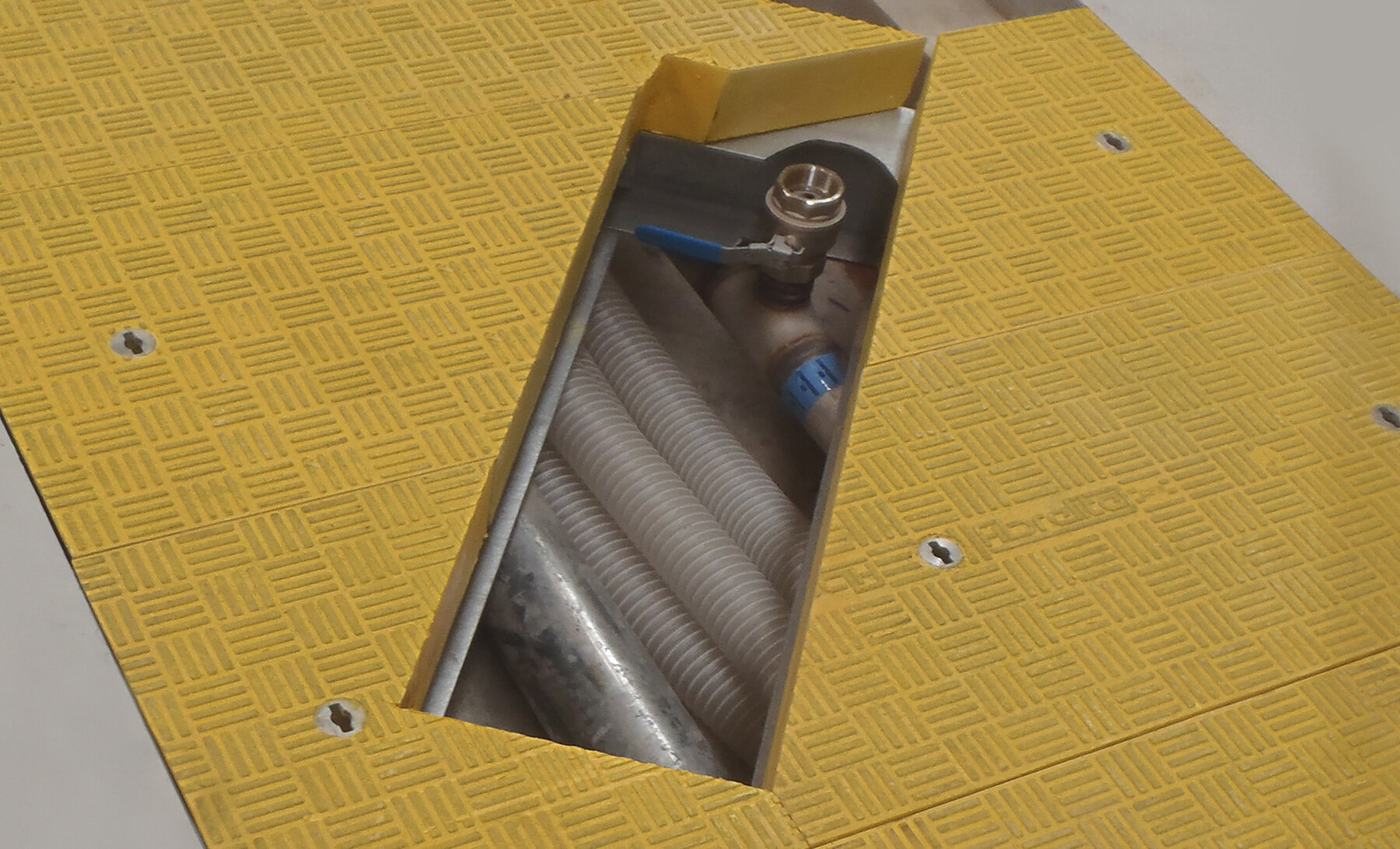

- Perfect for access to drains, ducts and piping

- Trouble-free lightweight durable monolithic structure which will not delaminate

- Corrosion-resistant: unaffected by water, underground gasses and most chemicals

- Excellent insulator against heat

- Non-metallic, non-conductive and will not spark

- Can be installed onto our specialised frame or an existing rebate

- Treads incorporate an anti-slip material equivalent to modern high-grade road surface

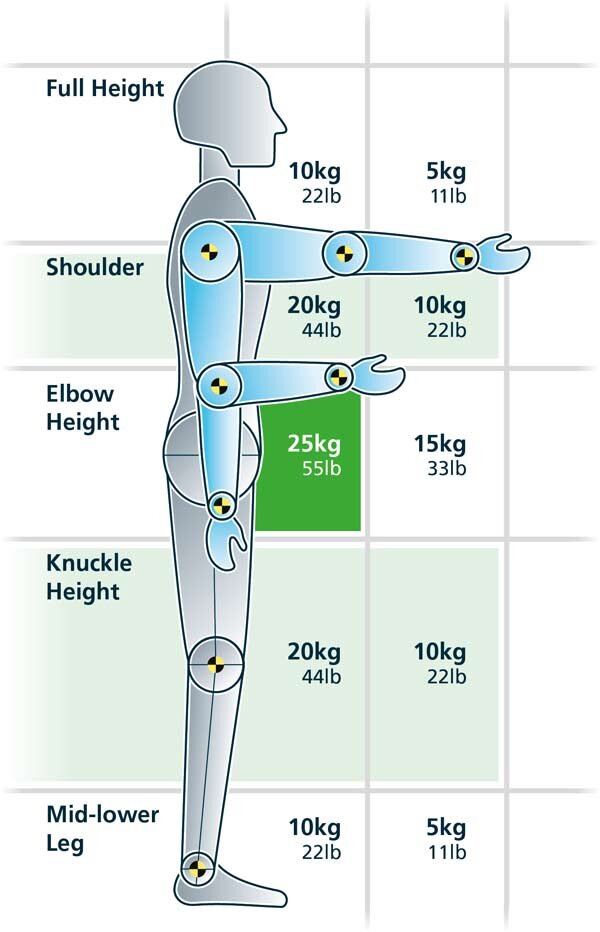

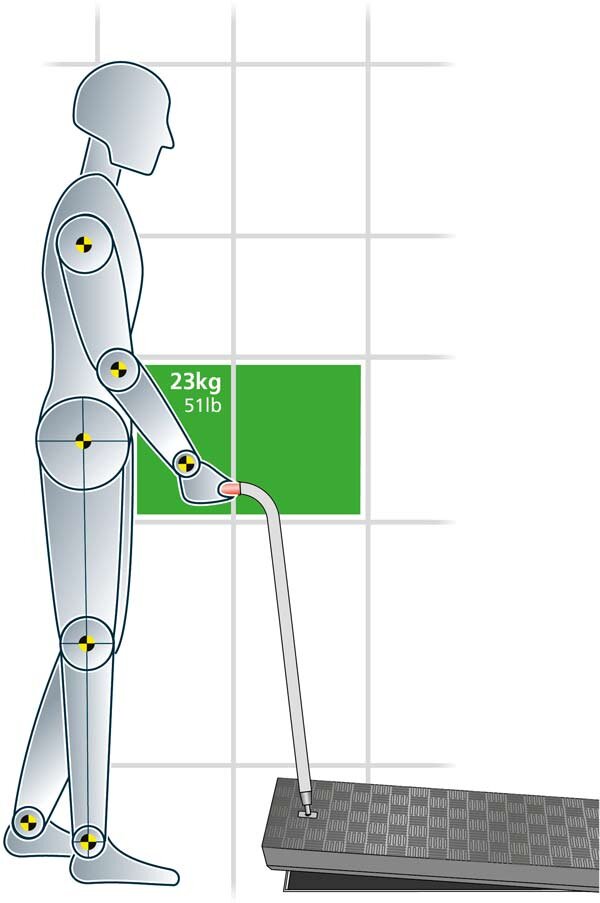

- Safe easy-lift manual removal using Fibrelite’s ergonomic lifting handle, eliminating the risk of back injury or crushed fingers

- Locks available

- Available in virtually any UV stable colour, which will not flake, fade or crack

- Logos or custom markings can be moulded into the upper surface

- Covers can be custom moulded to accommodate pipework entry, shallow depths with stepped cover profiles, steam and gas release vents, inspection ports and much more

Ultra-Durable

Designed as a fit-and-forget product, our GRP composite covers are maintenance-free, durable and very strong.

Read our Wear Resistance Test Report (Refer to clause 3.2.1 and 3.2.2, Page 14)

Read our Impact Resistance Test Report (Refer to clause 4.2, Page 15)

Corrosion-Resistant

A prime reason for selecting a composite cover is for its inherent resistance to corrosion. This makes it an obvious choice where water, waste water or corrosive liquids are involved. Fibrelite covers are also ideal where underground infrastructure requires protection from external corrosive compounds, such as salt.

Read our Corrosion Resistance Test Report (Refer to clause 3.1.5 & 4.4, Page 14 & 15)

Skid-Resistant

Independent wet and dry tests carried out by Devon CC Materials Laboratory showed that Fibrelite trench covers – even when wet – had anti-slip properties equivalent to a modern high grade road surface – far exceeding health and safety advisory limits.

Heat-Resistant

The thermal gradient properties of a composite steam cover significantly reduces the heat transfer from a steam vault to the surface of the cover. Typically, the surface temperature of a composite cover is only slightly above ambient temperature, even when subjected to extremely hot temperatures on the underside.

In fact, Fibrelite’s high-quality steam covers maintain their cool-to-touch properties and ability to support vehicular loads, even when pushed to a test temperature of 400°F.

“…I think Fibrelite is a great solution to a difficult design problem for us, of achieving both a robust and high load capacity cover to the multicore cables running from stage to control desk whilst maintaining low weight and easy access.”

Jonathan Size, Foster Wilson Architects

World’s Largest Range of Options

Fibrelite’s composite covers are available in almost any size, colour, shape and configuration, providing a truly bespoke, made-to-measure solution for every project.

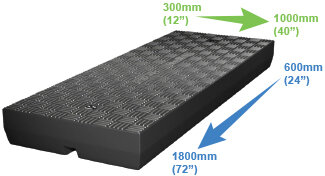

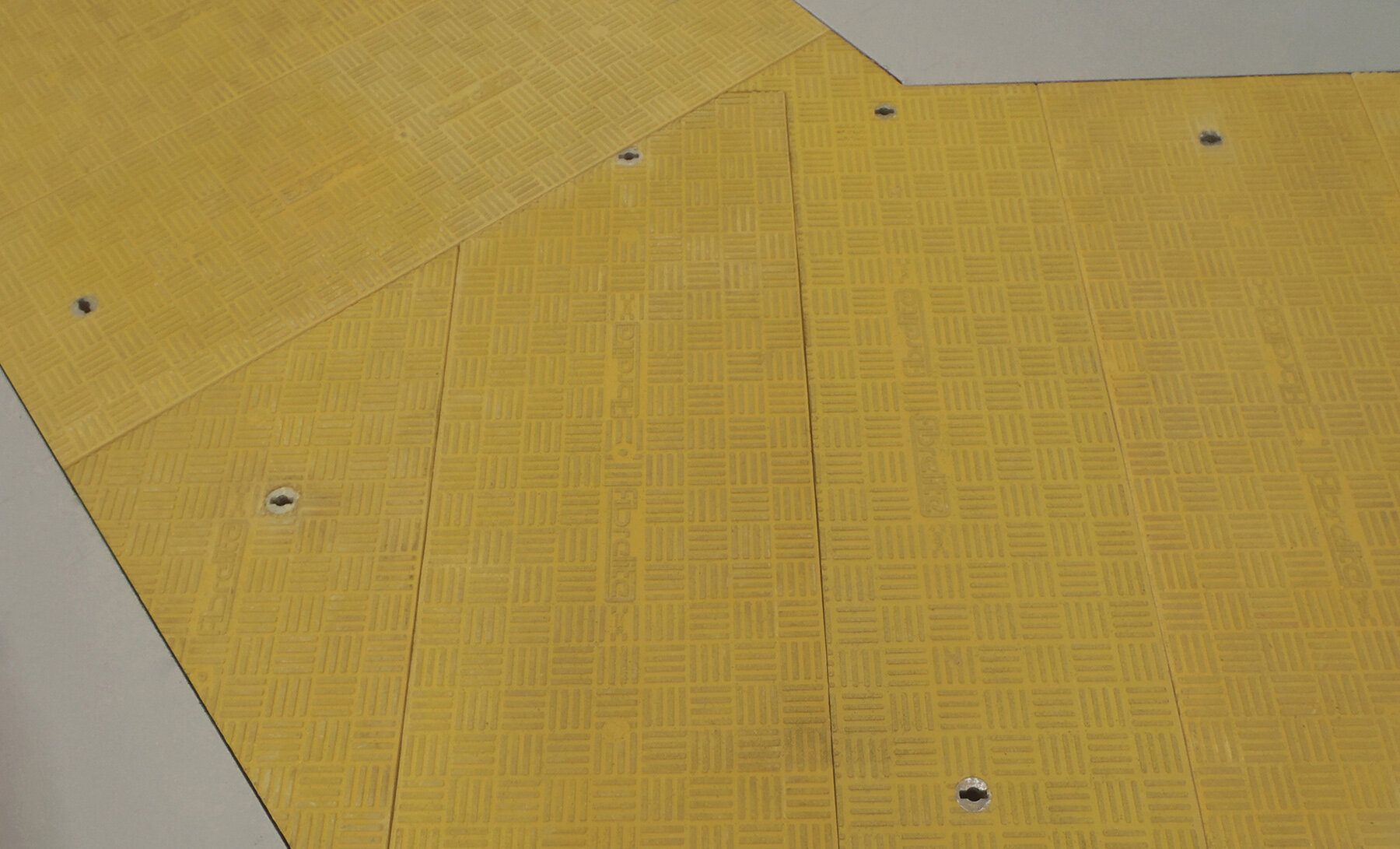

- Available in a range of widths from 300mm (12″) to 1000mm (40″); a range of lengths from 600mm (24″) to 20000mm (78 ¾”) and depths from 50mm (2″) to 203.2mm (8″). Custom sizes are also available. Load ratings are available from A15 to F900.

- Can be moulded in virtually any colour. As the pigment is added into the resin during manufacture, there are no issues with colour scratching or fading over time.

- Covers can incorporate logos, symbols and/or be colour-coded to match a facility’s branding, or even to identify the specific underground service that can be accessed via a particular cover. Read our Colour Fastness Test Report (Refer to clauses 3.2.1 to 3.2.3, Page 14)

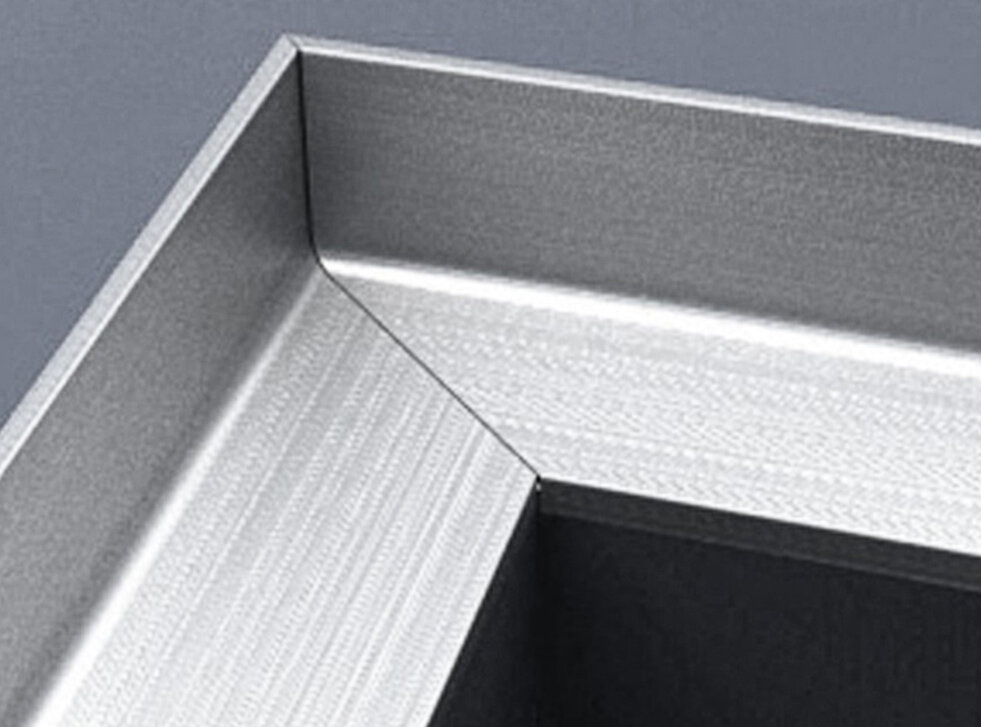

- Can be installed onto our specialised frame or existing rebate.

- Can be custom moulded to accommodate pipework entry, shallow depths with stepped cover profiles, steam and gas release vents, inspection ports and much more.

- Options available for all budgets up to the highest qualities.

Colours

Custom Moulded

Specialised Frame or Existing Rebate

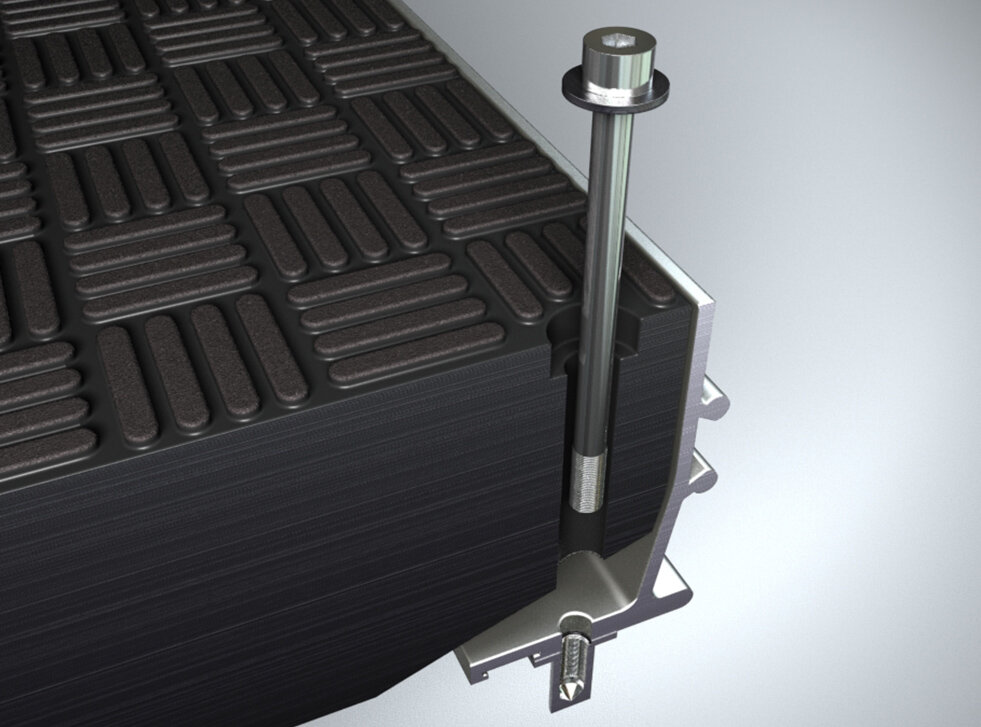

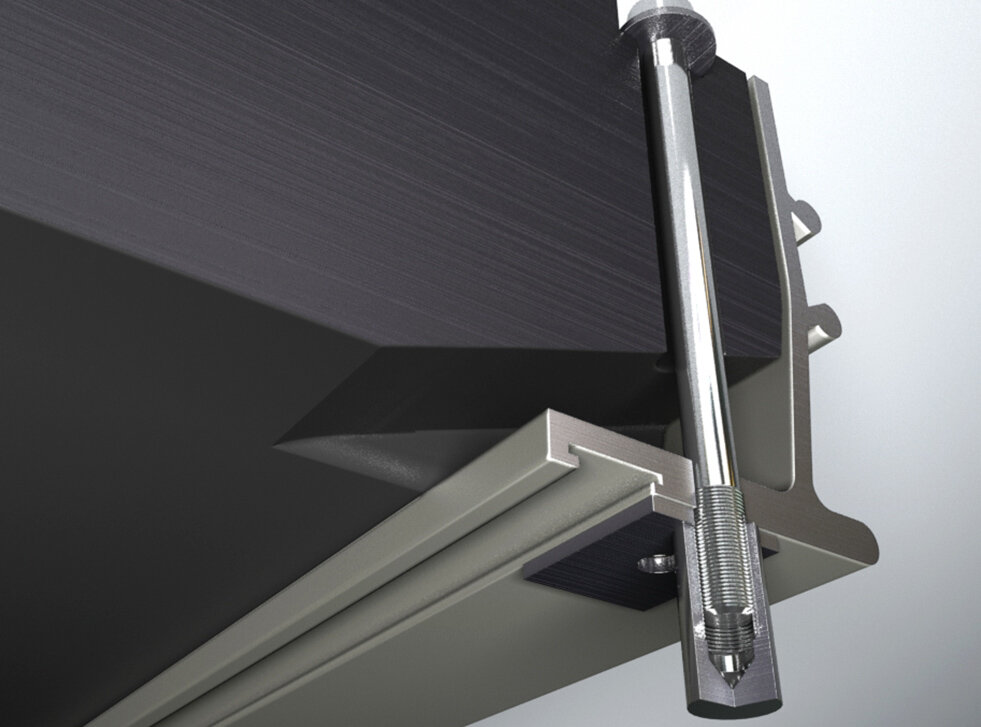

Locks and Restraining Bolts

Fibrelite Covers Can Be Moulded and Shaped to Accommodate Almost Any Trench Opening

“Dakin Contractors have worked with Fibrelite for over 20 years now and we are happy to recommend Fibrelite to any company looking to utilise their services. We have always found Fibrelite to be the leader in their market…a company driven by providing a product and a service that their customers desire and are constantly striving to improve their product in response to customer feedback. Fibrelite provide top class products at competitive prices and back their products up with an excellent on-site service.”

Contracts Manager, Dakin Contractors

Ergonomically-Designed

As well as being lightweight – typically a third of the weight of an equivalent-size cover produced in metal or concrete, Fibrelite’s ergonomically-designed lifting aid also eliminates the risk of back injury and crushed fingers.

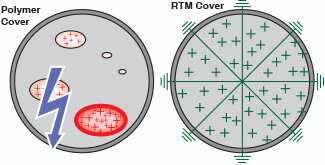

Fully-Conductive

Potential electrostatic discharging can be eliminated by using our “fully conductive” covers. We use a metallised fibre within the moulding process to achieve electrical continuity across the entire surface of the cover – and exceed the surface resistivity requirements of PAS26.

While the standard calls out for a maximum value of 1 KΩ/cm²; Fibrelite covers actually achieve a value of 0.0144 KΩ/cm².

Read our Conductivity Test Report (Refer to clause 3.1.5, Page 14)

Tried, Tested, Accredited

Fibrelite has held accreditation to the ISO quality standard (ISO 9001:2008) and British Standards Kitemark since 1998. This commitment to product excellence enables us to provide the most comprehensive range of high strength modular and custom-made trench covers, with the very best strength-to-weight ratio available in the market today.

Our Covers

- exceed H20 and H25 load rating standards

- are BS EN 124 compliant often surpassing the relevant class conditions for deflection under load

- are BSI Kitemark approved products

- have been independently tested to ensure that they meet AASHTO (American Association of State Highway & Transportation Officials) standards.

Technical Resources

Each product is fully supported with dimensional product drawings and installation instructions which you can access by following the links from each product page on this website, or by contacting us directly via + 61 2 9725 9000 or orders@liquip.com.

Don’t Just Take Our Word for it…

An 18” square, raised cover manufactured and supplied by Fibrelite was put through testing as specified in BS EN 124 after 14 years solid service on a high-traffic forecourt. The test report confirms the cover easily passed and it was notable that the orange colour had not faded, indicating that weathering and UV have no or very little impact on the performance of the Fibrelite cover over a sustained period.

No Risk of Theft

There is no risk of theft with a Fibrelite composite cover as composites have no resale value in the scrap market – so you won’t be left with a dangerous, uncovered hole in the ground.

Fibrelite in the Press

Here’s a quick round up of some of the recent Fibrelite stories which have made the news around the world. To read more click here.

Read more about our trench cover installations for water facilities:

Read more about our trench cover installations in a US Data Centre:

Read more about our recent manufacturing performance:

Unrivalled Strength-to-Weight

The Ultimate in Composite Engineering

LIQUIP GLOBAL PRESENCE

Africa, Asia & Pacific Islands, Australia, Europe, India & Sub Continent, Middle East, New Zealand, North & Central America, South America

Click here for a list of all Liquip distributors