Liquip provide a complete turnkey truck loading stations (gantries). Our engineered solutions incooperating Liquip's locally manufacted components are ideal for downstream bulk fluid handling, storage and transfer applications.

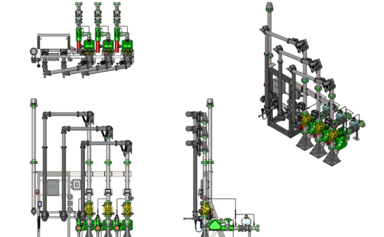

Liquips integrated skids are designed to meet customer and environmental requirements whilst providing the most productive, cost efficient and user friendly solutions.

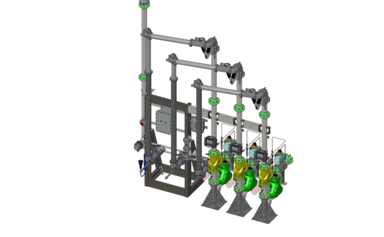

Loading skids designs vary form the most simple single arm with mechanical registers and printers to the 6 arm skids which can include blending, additive injection, quick flush tanks, fuel management systems linked to a gantry operated control connected to the site terminal automation system.

Our Specialties

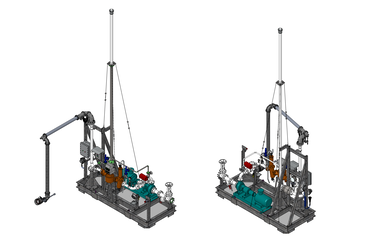

- Aviation loading skids

- Tank truck loading skids

- Additive injection

- Blending

- Quick flush tanks with platform

- Extension Skids

- LPG Skids

- Mining, Oil and Gas

- Marine

Our Process

->As part of our design process, we start with an assessment of the customer requirments. Our dedicated technical team will design a solution and produce a detailed General Arrangement (GA) drawing for customer approval.

-> This GA drawing will provide a comprehensive overview of the major components and key diemensions.

-> Once the GA drawing is approved we will complete the detailed design and begin construction following through to wet testing and operational confirmation.

-> The final stage will be arranging packing in line with customers requirements before collection.

Our Services

Mechanical Design

- Produce high-level piping system designs, including piping and instrumentation drawings (PIDs).

- Produce high-level piping layouts, with consideration to operability, functionality, and safety.

- Plan and conduct Hazard and Operability Studies (HAZOPs

- CAD modelling.

- Coordination with multi-disciplinary parties.

- Designs incorporating:

- AS4041: Pressure piping

- AS4037: Pressure equipment - Examination and testing

- AS1657: Fixed platforms, walkways, stairways and ladders

- AS1940: The storage and handling of flammable and combustible liquids

- AS2809: Road tank vehicles for dangerous goods

- AS3992: Pressure equipment - Welding and brazing qualification

- AS4458: Pressure equipment - Manufacture

- AS/NZS60079: Explosive atmospheres

- AS3788: Pressure equipment – In-service inspection

Electrical Design

- Detailed Design

- Coordination with multi-disciplinary parties

Fabrication

- Detailed Design, fabrication and installation of piping and mechanical systems.

- ISO9001

- Specialsed welders.

- CSWIP 3.1 welding inspector

- Material traceability

- Welding procedures WPQR and WPS as per Australian standards.

- Qualified boilermaker welders

- Full package MDR with Hydrotest certificates and detailed ITP

- 3rd party verification of calculations.

- Paint testing, measuring and reporting systems including dry film thickness, adhesion and humidity reports, along with spark testing.

- Hydrostatic Testing

- NDT and X-ray testing

- Quality / Inspections

- Documentation to ISO 9001

- Manufacturing to LEAN/KANBAN

Features and Benefits

- Expert assessment consultation

- Designs the most cost effective solution

- Delivers pre- and post-sale support

- Offers a complete line of loading skid components

- Single Source

- Plug & Play Solutions

- Durable and low-cost systems, that reduce total cost of ownership.

- Flow rate up to 2500L/min

- Can withstand harsh and remote environments.

Key Components

- Loading Arm

- Overfill Protection

- Pump

- Meter

- Air Eliminator

- Terminal Control System

- Filtration

- Additive Injection

- Temperature Probe (optional)

- Flame Arrestor (optional)

Site Preparation Considerations

- Driver side of tanker

- Truck drive in direction

- Frame work

- Full frame with Maintenance Walkway

- Platform style frame work

- Skid Foundations

- Spill tray

- Grating

- Concrete

- Fuel entry pipes

- Fuel Max Pressure

- Drive way sump & Slops return

- Modular Frame work with expansion allowed

- Container size frame work for shipping

- Number of loading arms or bays